Corte láser en acero inoxidable de alta calidad y además con tiempo de entrega oportuno, eso es lo que te ofrece SUMIPARTS S.A.S., Suministros Industriales. Si lo que buscas es precisión en tus trabajos mecanizados de corte láser, Sumiparts es tu mejor opción.

El corte láser en acero inoxidable es una de las especialidades de SUMIPARTS. Realizamos distintos tipos de corte para hacer realidad los trabajos de mecanizados de precisión de nuestros clientes. En función del objetivo y la pieza a mecanizar, decidimos entre un tipo de corte u otro, y uno de los más habituales y que mejores resultados ofrece, es sin duda el corte por láser en acero inoxidable.

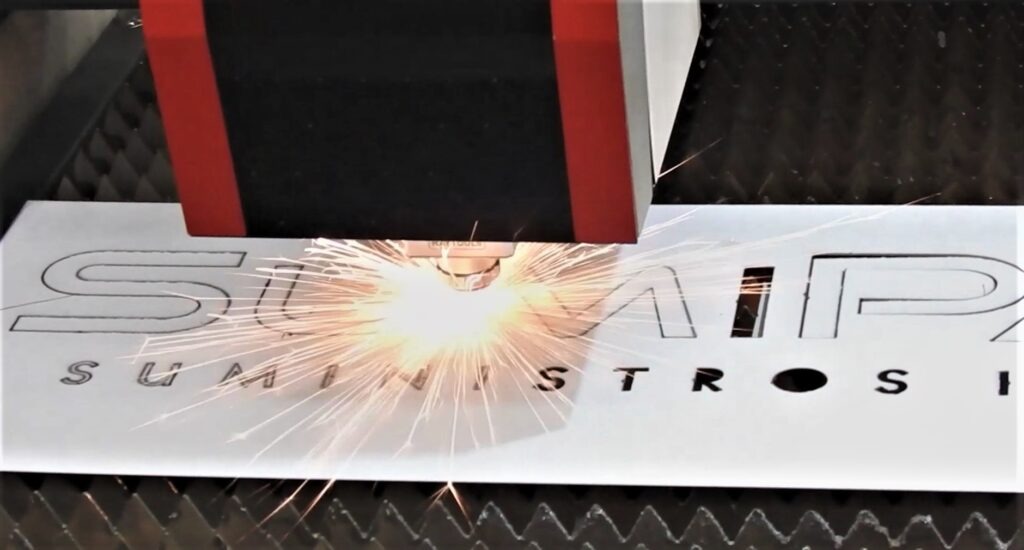

Nuestro sistema de corte láser permite obtener piezas complejas y el resultado final alcanza la profundidad y la geometría necesarias para tu proyecto.

El corte láser en acero inoxidable de SUMIPARTS es mucho más rápido para trabajar, que otro tipo de cortes. Además es muy seguro, pues no necesita ni ser enderezado ni fijado. Con el corte láser se obtienen piezas completamente limpias, sin rebordes ni deshilachamientos.

CORTE LÁSER VS PLASMA

Si nos preguntamos por el corte láser y su proceso, es bastante sencillo: El mecanizado láser se basa en el corte de chapa por láser, es decir, con un láser como fuente de energía concentrada sobre la pieza. Este tipo de corte se utiliza especialmente para cortes previos o para el corte de material sobrante. Es un corte poco convencional, pero que permite obtener piezas complejas. El rayo láser erosiona el material de la pieza en varias capas, para conseguir la profundidad y geometría necesarias.

El corte por láser en acero inoxidable es mucho más rápido para trabajar que otro tipo de cortes. Además, es muy seguro pues no necesita ni ser enderezado ni fijado. Gracias a esto, el personal encargado del trabajo no está nunca en contacto con la pieza. Por otra parte, los cortes que se obtienen están completamente limpios, sin rebordes ni deshilachamientos.

Una de las preguntas más habituales es láser vs plasma. El corte por plasma se basa en enviar un chorro de gas ionizado a gran velocidad. Este gas ionizado es el plasma, que conduce la electricidad desde la antorcha a la pieza a mecanizar. El corte por plasma se puede aplicar sobre cualquier tipo de material y no es necesario un operador. Por lo que, si estamos entre plasma vs láser, la solución es saber primero el objetivo del trabajo de mecanizado.

Si deseas saber más sobre este servicio de corte laser en acero inoxidable en SUMIPARTS estaremos en la mayor disposición de colaborarte. Deseamos brindarte los mejores servicios al alcance de tus manos. Ponte en contacto con nosotros llamando al Pbx: +57 748 22 13, Cel: 313 699 13 56 whatsApp click aquí o enviando un correo a info@sumiparts.com. Nuestro equipo técnico estará en toda la disposición de atenderle, te dejamos unos links que pueden ser de tu interés 5 Beneficios de usar mecanizados CNC , Inyección de TPU